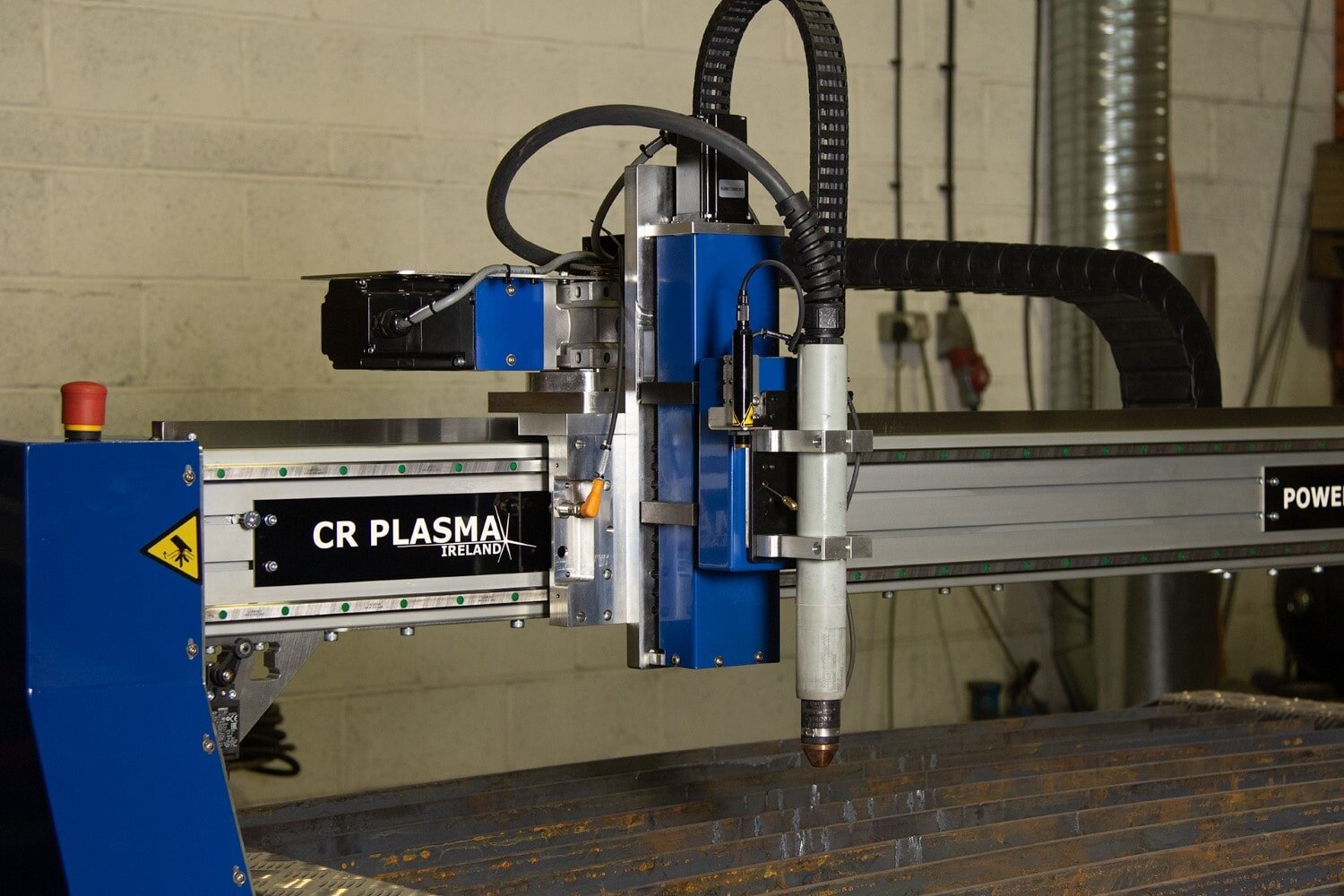

CNC Plasma Cutting Machine Solutions

At CR PLASMA, we build a range (POWERCUT) of high-end, very affordable, industrial-grade CNC plasma cutting systems & CNC plasma cutting tables. With our own in-house expertise in plasma-cutter and CNC technology, we bring you industrial-strength plasma cutter performance and reliability at an affordable price.

THE POWERCUT

Many power source options, different table sizes, and all machines come with the CR PLASMA controller and support platform.

CR PLASMA POWERCUT Cutting Box Section

Check out the machine here being used to cut 150 x 200 x 3mm wall box sectoin

Our POWERCUT CNC Plasma Cutting Range

• POWERCUT 10 × 5 CNC Plasma Cutter (standard definition) is the most popular machine in our range and forms the basis of the plasma system in all our products. The standard POWERCUT runs a PMX 125 from Hypertherm and can pierce and cut 25mm steel plate.

• High Definition POWERCUT 10 × 5 CNC Plasma Cutter

The POWERCUT is offered with the Thermal Dynamics UltraCut XT 200A plasma power source fully integrated. The system can run high definition cutting of steel with oxygen, and also with water mist and nitrogen for cutting stainless steel.

• 4000 × 2000 Portal Plasma Cutter

Our 4000 x 2000 mm CNC plasma system runs on steel islands that are bolted to the floor of the location where the machine is installed. Paired with other innovations the result is a very smooth efficient drive system to move the bridge up and down the machine. The machine is offered in standard and high definition power source configurations

• 6000 × 2000 Portal Plasma Cutter

The 6000 x 2000 mm portal plasma machine is used to allow loading of two full sheets 3000 mm long at once. Even at 6000 x 2000mm stroke the machine still maintains the same high-level accuracy and hole quality of the standard POWERCUT. The machine is offered in standard and high definition power source configurations

• Ducting Plate Rider System

The plate rider system can be fitted to any of our machines. When cutting thin sheet materials like galvo for ducting it’s better to run with an air-driven plate rider system. Our plate rider system is fully machined out of alloy and designed to maintain robust accurate control of the torch position.

• Water Mist Technology

The Thermal Dynamics UltraCut XT 200A plasma system offers a one torch plasma solution for high definition cutting of mild steel and water mist cutting of stainless steel.

• High definition OPTI HOLE Integration

the CR PLASMA controller has OPTI-HOLE fully integrated into the 200A Ultracut XT platform. We have fully optimised torch motion across all the settings to bring the OPTI HOLES quality to the CR PLASMA POWERCUT.

• POWERCUT CNC Control Software

Our control software has a fully customized GUI specifically designed to connect the operator to the process. All settings and torch states are on the front screen or a click away. Features like cut recovery, go-to position, rip cutting, plate alignment, laser pointer assisted setup, auto squaring are all standard features on all machines.

Custom Design Machines

We can build you a CNC plasma cutting machine of almost any size you need and tailor the machine to your specific needs. We have standard 10 x 5-foot models that we usually stock. We can build 4-foot x 4-foot models and 4-metre x 2-metre models. Or feel free to request a custom size to suit your business needs.

Highest Quality Parts

We are not a box to box company. We build all our machines out of the highest quality European sourced parts and components. The result is a very reliable platform to carry out heavy plasma cutting production schedules. We strive to always deliver the best plasma cutter solution possible.

Finance Options Available • Exceptional After-Sales Service

If you work with us we will not just provide you with a machine, we will provide you with a production solution. We can provide finance options when purchasing and we will help you get set up and enter into full production quickly with full training packages available.

Cut Steel to a Finer Tolerance – Every Time

Our machines will position the plasma torch to below 0.1mm of accuracy. The CNC controller will then control the movement to within 0.1mm of what you have designed in the drawing. The result is the same part size every time. No manual plasma torch work is needed. The CNC control system takes control (also with level/height control).

Reduce Waste • Speed Up Production • Rapid Payback

Our CNC plasma cutting system can help you reduce steel waste by allowing nesting and part layout optimisation. The cycle time per part will reduce significantly when compared to manual cutting. The result is a rapid payback on your investment when parts in large or small volumes are needed.

Easy-to-Use Software

We have set out from the start to keep the software as easy to use as possible. The workflow is very straight forward and you do not need to be an IT expert to use the machine. The interface is clean and easy to follow. With a few simple clicks, you are cutting steel with ease.

Specific in-house expertise in CNC systems and control with CNC experts StoneyCNC.

We have teamed up with StoneyCNC who have over 1000 CNC controlled systems in the field. The result is a fundamental knowledge of the inner workings of every machine.

Our CNC plasma cutters/CNC plasma tables are for sale online via our shop at Stoney CNC and Allister Moore Welding and of course directly if you contact us.

“From a total novice on the PC to a plasma cutting operator. The lads at CR plasma were really helpful to get us up and running when we knew very little about CNC plasma cutting.”

We pride ourselves in building the best programmable plasma cutter table for anyone with serious metal fabrication/metal workshop equipment needs. Get your plasma cutting table with superior cut quality.

If you are looking for the best plasma cutter or a plasma table for sale, you have come to the right place.

CNC Plasma Cutters for Sale

In addition to the CNC plasma cutters we manufacture and sell, we sometimes also refurbish and sell used/second-hand CNC plasma cutters. If you would like to register your interest in a used CNC plasma cutting machine that becomes available, please contact us.

More details: CNC Plasma Cutters for Sale, High Definition CNC Plasma Cutters for Sale

Used CNC Plasma Cutters for Sale

More details: Used CNC Plasma Cutters for Sale, Used High Definition CNC Plasma Cutters for Sale